Replay: How to improve output and productivity with net-weight filling machines in Asia?

The paint industry in Asia is constantly moving forward. Faced with growing demand and increasingly stringent environmental regulations, players in this sector are faced with numerous challenges.

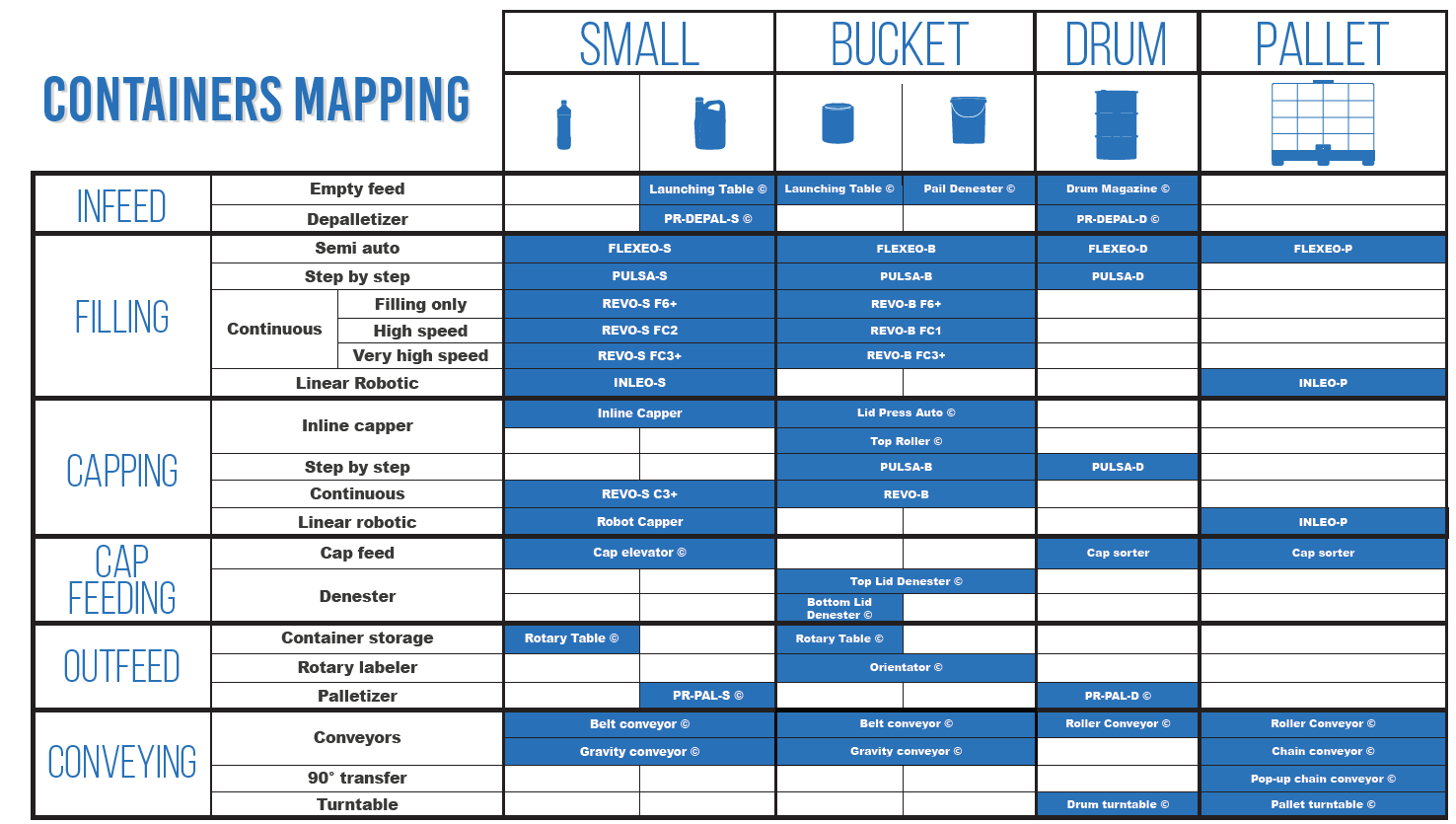

Filling products in the paint industry means adapting to the variable properties of the products, the multiplicity of containers, the materials used and the different production output. These products can be dangerous, toxic or even flammable.

In this replay of our webinar, we explored the key issues you’re facing in Asian countries:

- What are the different filling technologies in the Paint Industry?

- Optimizing production processes: How to enhance the efficiency, precision and flexibility of your production lines while reducing costs and waste?

- Which filling technologies to choose?

- Real success cases

You fill paints, inks, coatings, lacquers, varnishes, wood protection products, thinners, solvents, and you want to know more about the right technologies to adopt? Watch this replay!

Complete the form and watch the replay!

SPEAKERS

Leading the Pack’R Asia team based in Singapore. Experienced professional with a strong technical background in packaging machinery, with more than 25 years supporting customers around Asia.

Dosing of liquid products - Weight dosing

Dosing of liquid products: which methods? Focus on weight dosing

Because dosing is a key step in the filling of liquid products, the two are sometimes confused in the common language of professionals. In practice, weight dosing is also called “weight filling”.

With an inaccurate dosing system, a filler-capper with an output of 120 packages/minute operating 24 hours a day, more than 8 liters of product will have been over or under dosed. When it comes to high value-added liquid products, the financial losses can be colossal.

What is batching?

In the packaging machinery industry for liquid products, there are 4 dosing methods:

- Volumetric dosing

- The debimetric dosing

- Visual dosing

- The weight dosing

The weight filling, also called gravity dosing, is a method to measure the quantity of a product by its weight. In the market of packaging solutions for liquid products, which includes foaming products, viscous products and products with a higher or lower density, weight dosing allows for precise filling thanks to a physical unit of measurement: the kilogram.

In fact, this method is suitable for all types of products and depends only on the machine’s scale. We use our patented “µPACKR” solution as a precise weight measurement. The weighing is subject to legal metrology.

Eliminating the discrepancies between the calculated quantity and the actual quantity delivered, the weight dosing allows :

- A bette follow-up the production ;

- A increase in Filling quality;

- A reduction of the marginal costs of the company.

At PACK’R, we have privileged the weight filling for :

- Its adaptation to the industries of our customers (Agrochemistry; Chemistry; Petrochimistry; Vegetable oils; Paint; Food);

- Its high dosing precision ;

- Its precise dosage, not affected by temperature variations ;

- Its economy of product because no overfilling ;

- The availability of legal metrology